With the emergence of high performance NdFeB rare earth materials, the development of magnetic tools using NdFeB permanent magnetic materials has become a trend, and permanent magnetic suction cups have emerged as the times require.

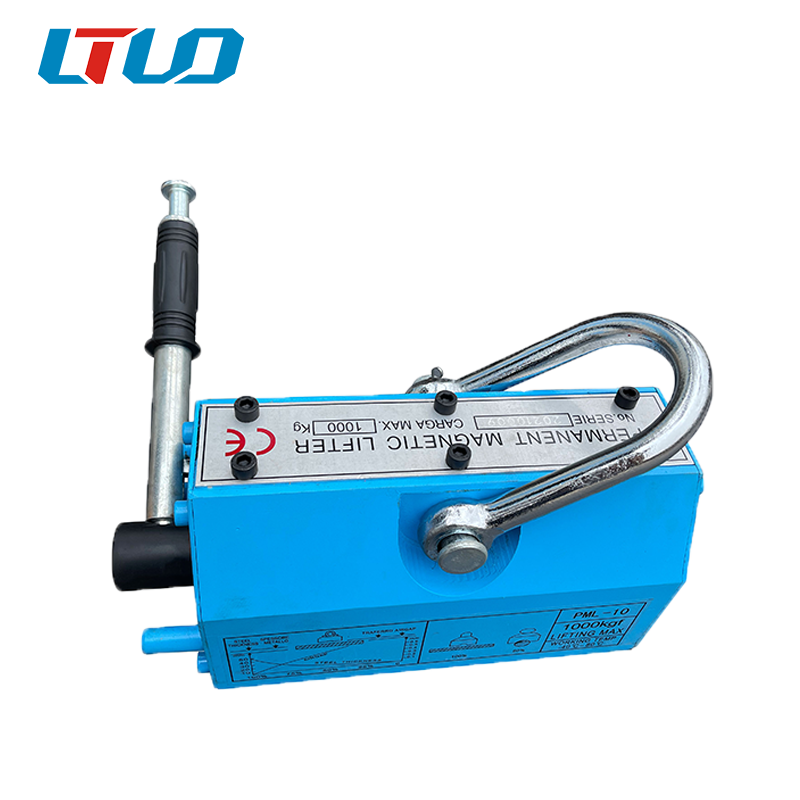

The permanent magnetic chuck, also known as magnetic chuck or permanent magnetic lifting device, is a necessary handling tool for machinery plants, mold plants, forging plants, steel mills, shipyards and other places where steel is used. It can greatly improve the handling efficiency of block, cylindrical, plate and irregular magnetic iron and steel materials. The permanent magnetic chuck is made of high performance rare earth material neodymium iron boron (N>40) as the core. It can change the magnetic system of neodymium iron boron in the chuck by turning the handle of the chuck by hand to achieve the holding or release of the workpiece to be handled. Principle of permanent magnetic chuck: permanent magnetic chuck is designed by using the continuity principle of magnetic flux and the superposition principle of magnetic field. The magnetic circuit of permanent magnetic chuck is designed into multiple magnetic systems. Through the relative motion of the magnetic system, the magnetic field strength on the working magnetic pole surface is added or eliminated, thus achieving the purpose of holding and unloading. Design of permanent magnet suction cups: When designing permanent magnet suction cups, the magnetic circuit should be carefully designed first. A good magnetic circuit structure can allow more magnetic flux to gather in the working surface as much as possible to meet the requirements of lifting weight, and neodymium iron boron materials can be used as little as possible. At the same time, when designing the magnetic circuit, the operator should also carefully consider that it is easier to realize the work unloading. Solve the technical difficulties such as large suction force of permanent magnet chuck and difficulty in pulling handle.

Next: How to select lifting belts?

Previous: How to identify the authenticity of steel plate tongs ordered online